Hardware Overview

The computer hardware for this project consists of the usual VME rack

and power supply and several cards.

The CPU board for this project is a Motorola mvme167 board which

contains a MC68040 chip with 4M of ram. This small amount of

memory is seriously taxed by running WindX user interfaces on

the control computer. Tests have shown that even without the

GUI code running, it is not possible to run the cell control

software on the slower MV68030 based mvme147 board.

In addition to the CPU board, we have an amazingly modest complement

of interface boards, only 2 besides the CPU:

- Greensprings VIPC610 carrier (VME short IO at 0xE000)

- Acromag 9330

16-bit ADC card (VME short IO at 0x0400)

The 4 IP-module slots are used as follows:

- slot A - empty (would be IP-DAC in the test stand)

- slot B - IP-precision 12-bit ADC.

- slot C - IP-digital 48 (mux control, etc.)

- slot D - IP-digital 48 (actuator DACs, etc.)

None of these use interrupts at this time (the acromag driver may be

updated at some point to use interrupts).

Timer interrupts (the timer is on the CPU board) provide a clock tick

at a 1000 Hz rate.

This fast clock is subdivided to activate tasks within the cell

software at appropriate rates, only a few tasks actually run at

1000 Hz.

Starting the Software

The cell computer (mmtcell) is a diskless machine running VxWorks.

When this computer is turned on, it attempts to get a copy of

VxWorks, as well as the cell software over the network from a boot

host (at this time, hacksaw). Once it has booted and started the

cell software, the network is no longer necessary, although it

will be impossible to give commands to raise and lower the mirror

without using the network. When the crate has booted, loaded

the cell software, and started the latter running, it produces

the "bouncing ball" display on the LED's on the front of the VME

computer.

At this point, it will be desirable to start a set of user

interface windows on some computer. This is typically done

on hacksaw by giving the command "vcell all". This command

sends a series of messages to the VME crate instructing it

to start X windows tasks (using the VxWorks hosted X library

"WindX" running in the crate). These GUI tasks display over

the network to some X server (typically hacksaw). These interfaces

are true "legacy code", and we are eager to reimplement them

with Perl/Tk or Ruby/GTK scripts.

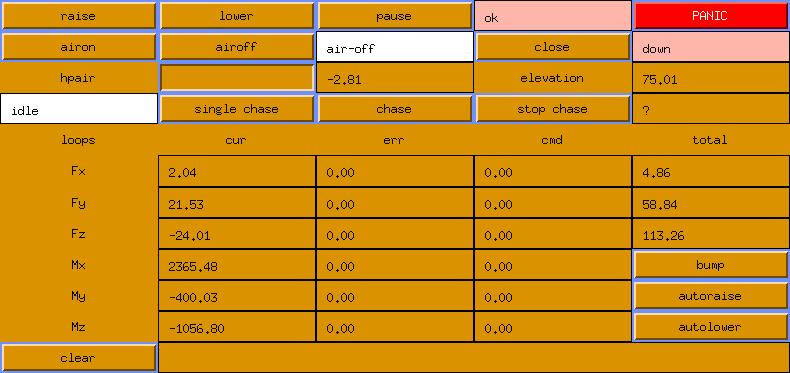

Raising the Mirror

Once the crate (mmtcell) is booted up and the user interfaces

are running, use the airon button to turn on the valves that

supply air to the cell. Use the bump button to run a bump test,

and if that goes OK, use the autoraise button to lift the mirror.

Whatever you do, do not use the raise/lower buttons in the upper

left corner of the control window (if you do, no harm done, but

let the raise finish, use lower to set it back down, then use

autoraise instead). Once the lift is done, use the position

window to apply any mirror tilts or position offsets.

Lowering the Mirror

Use the autolower button. People often ask why it takes so

long to lift and lower the mirror. It is all a question of

how fast the stepper motors that extend and retract the hardpoints

can be stepped. We limit the mirror lift to keep the hardpoint

breakaway mechanism engaged throughout the lift or lower.

Stopping the Software

Once the mirror is down, you can power off and/or unplug the

cell crate. Rebooting or unplugging the cell crate while the

mirror is up is to be avoided at all costs. Doing so will

cause the electronics the drop the mirror in an abrupt and

hard to predict fashion.

Panics, Errors, and Limits

The cell software uses the term "panic" for the action it takes

when it finds an unacceptable condition.

Numerous checks are performed constantly by the software while it

is running. Any of these may be viewed as a possible hazard to the

mirror, and will result in what is called a "panic".

Because the software has identified a dangerous condition that it

is unable to correct or control, the action it takes is

to deactivate the air control valves.

This results in as rapid an evacuation of air pressure

as has been deemed safe from the support system, resulting in

an almost immediate dropping of the mirror onto the static supports.

The control window provides a "panic button" which the operator

can use at any time to cause this to happen. A mirror panic is

always a safe option at any time the operator identifies an unsafe

condition, although simply lowering the mirror is the better choice

if conditions permit.

It is a fundamental design concept that a panic is always an acceptable

option, and the software at any time can take evasive action by panicing

the cell. A key example where the only possible option is a panic is

when a actuator control DAC fails in such a way that it is commanding

a maximum force regardless of computer command (we have had two DAC's

fail in this way thus far).

The following limits cause panics or in some cases truncation of

commanded forces to the limit value:

- Actuator X force: +- 400 pounds

- Actuator Y force: +- 450 pounds

- Actuator Z force: +- [0,G00] +- 90 pounds

- Total X force: +- 5000 pounds

- Total Y force: -800 to 22000 pounds

- Total Z force: -800 to 22000 pounds

- Total X moment: +- 160000 inch-pounds

- Total Y moment: +- 40000 inch-pounds

- Total Z moment: +- 40000 inch-pounds

The individual Y force limits are interesting, since we have

50 duals, and the mirror weighs 20900 pounds, when horizon pointing

each must exert 418 pounds to support the mirror, we have an excess

ability of 1600 pounds to respond to disturbances. The total Z and

Y force limits give an excess of 1100 pounds, which is perhaps too

tight. Perhaps even more interesting, consider our 6 square inch

area piston being delivered 100 psi air. It can produce a 600 pound

force, but multiply this by .7071 since it is at a 45 degree angle

and we get 424 pounds; just a bit above what we need. If we supply

120 psi air (and we intend to), we will get 20 percent above what we

expect to need, and a 20-30 percent "headroom" is about what we think

is right.

Outer loop transient testing

This section is pretty out of date, but here it is until we

document some new and improved facilities.

There is a program called xtran that can be run on hacksaw

and which communicates via sockets with the cell computer to do

this testing. One way to invoke it is:

xtran 10 >data

This requests 10 seconds of outer loop data and places it into a file

called data. The outer loop runs at 37 hertz and presently we collect

the transient data at the outer loop rate, so this will be a 370 line

ascii file. A limit of 100 seconds of data is imposed. The file

consists of 12 columns. The first 6 columns are forces and moments in

the order Fx, Fy, Fz, Mx, My, Mz. The last 6 columns are hard point

lvdt readings transformed into sensible

coordinates in the order: X, Y, Z, tilt-X, tilt-Y, tilt-Z.

More interesting is to bump the target value for one of the loops

and look at the transient response. This is done via the command:

xtran 10 2 20. >data

As above, this collects 10 seconds of data (370 points), but 2 new

arguments specify a loop and a bump value. The loop selector (2 in this

case) is a number from 0-5, and the value after is a force increment in

pounds, or a moment increment in inch-pounds. Notice that these are

given as increments to the current loop target, rather than as a new

loop target. The loop selectors are as follows:

- 0 - X force

- 1 - Y force

- 2 - Z force

- 3 - X moment

- 4 - Y moment

- 5 - Z moment

Graphing xtran data

We used to do this with iraf "graph", and you still can if you choose

to do so. We also have (or had) awk scripts to pull columns out of

the file to be fed to a graphing program. The following documents

on way of making graphs, circa 1988 or so:

First to run a command to yank the column of interest out of the file.

There are several scripts named "getfx", "getmy" and the like

that are invoked like this:

getfx data >xfile

Running IRAF and invoking graph are a world of issues unto themselves,

but the following worked pretty well once upon a time:

graph xfile

If you want paper copy invoke the graph command as:

graph xfile dev=stdplot

Don't forget to gflush, (sigh!).

GUI Screen Shots

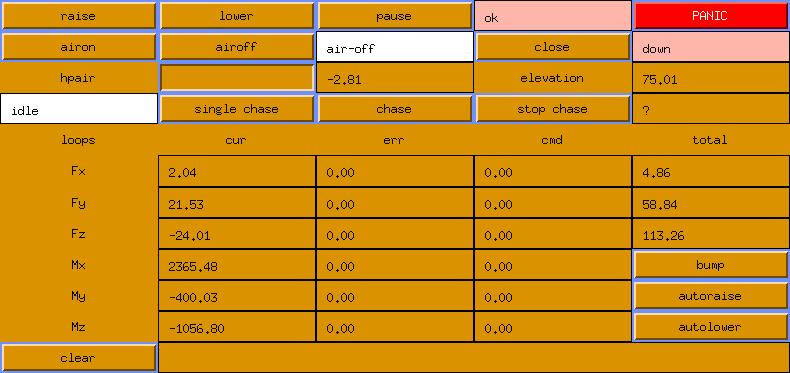

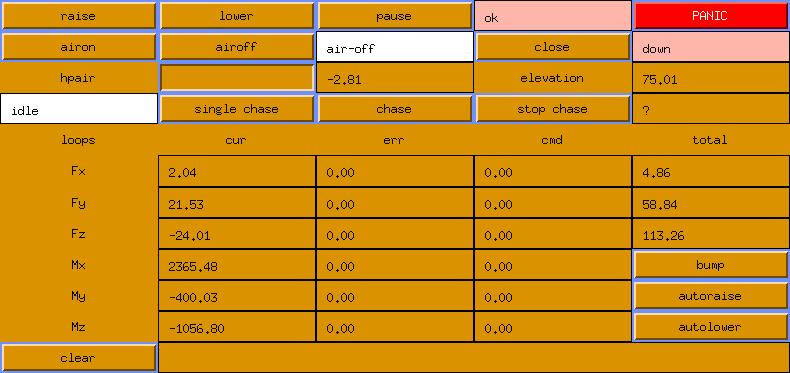

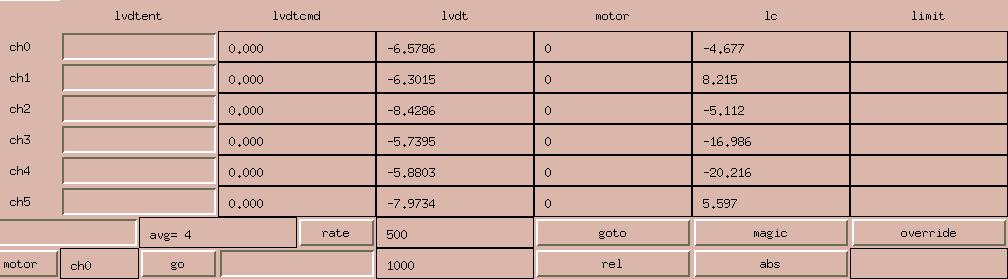

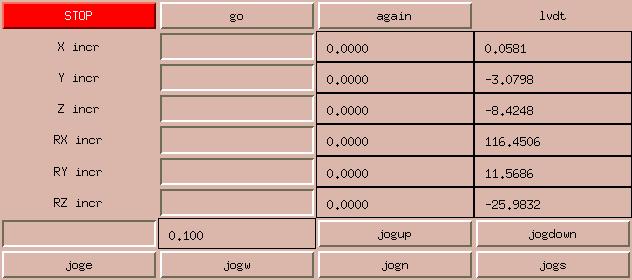

Here are some screen shots of the GUI that we use to

control the cell software. This ancient and funky GUI is

implemented using WindX (X windows running directly in the

VxWorks computer), but has served us fine for years, here

you go:

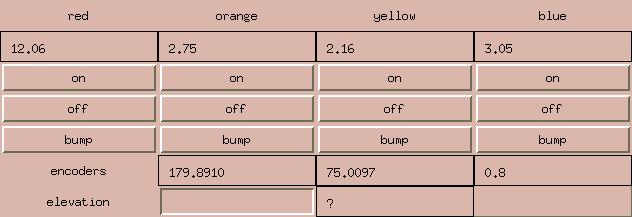

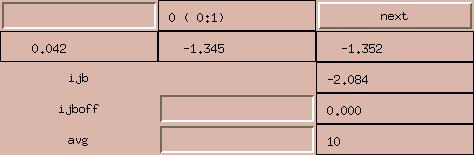

Here is the control window (xcell1)

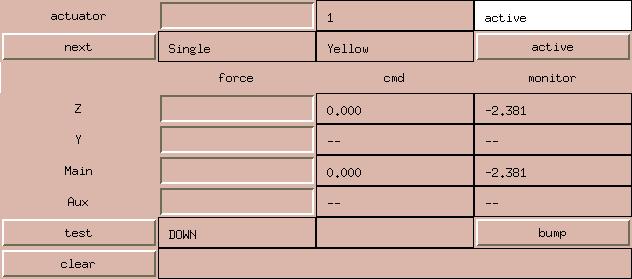

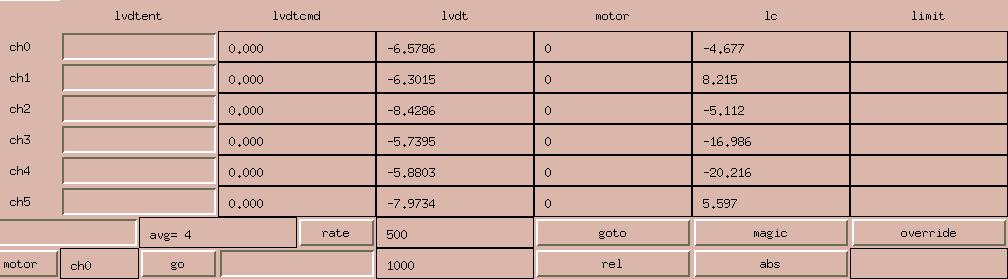

Here is the hardpoint window (xcell0)

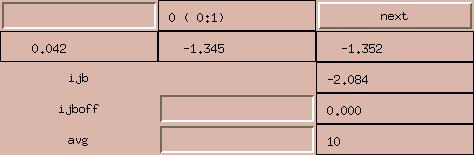

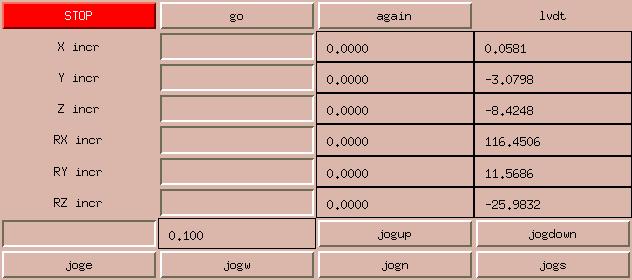

Here is the position window (xcell3)

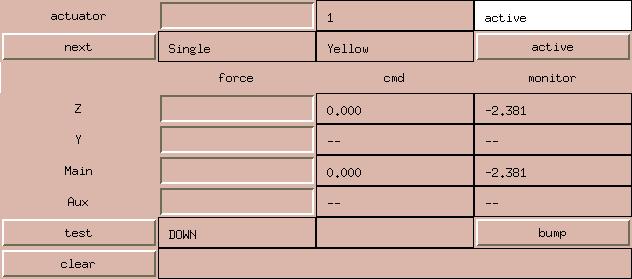

Here is the actuator window (xcell4)

We only use this to diagnose problems

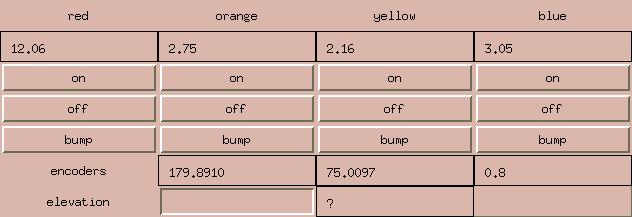

Here is the air window (xcell6)

We almost never use it though.

Here is the thermocouple window (xcell5)

We absolutely NEVER use this one.

Actuator Calibration

A test stand has been built and used to test and calibrate actuators

outside of the cell. This test stand has its own vme chassis and card

complement, and can be run independently of the cell itself. It uses

2 dac channels on an IP-DAC module in slot A of a VIPC610 carrier to

command the actuator. The stand has 6 load cells which allow it to

monitor forces and moments on and around any axis. Additionally,

the load cells on the actuator are monitored as well. All load cells

are monitored by an Acromag 9330 16-bit ADC board.

The test stand is controlled via a serial terminal (nothing else

was provided, so we dug this out of a closet). A more razzle-dazzle

interface may be worked up someday, if we run out of more important

things to do and some appropriate hardware is obtained.

Each actuator is subjected to the following "autocalibration"

procedure. The actuator is bolted to the test stand and connected

to a bottle of pressurized nitrogen at 120psi. The software then

performs the following sequence:

- Set the DAC volts per pound to the nominal values (.01491).

- Disable the integrator.

- Command a force of 0.0 pounds (on both axes).

- Wait 10 seconds.

- Read the test stand values and record them as offsets.

Typically a Z force of 70 pounds will be obtained.

- Enable the integrator.

- Wait 10 seconds.

- Read the test stand values and record them as offsets.

A Z force of nearly 0 pounds ought to be obtained.

- Command actuator 1 to 300 pounds.

- Read the test stand values.

- Calculate P1 = 0.01491 * 300. / Z-stand.

- Calculate PM1 = P1 * actuator load cell / actuator dac.

- Set the dac volts per pound to P1

- Command actuator 1 to 300 pounds.

- ... To be continued ...